B&W Engineering: Managing Sustainability in Construction

As sustainability continues to grow in importance both to investors and consumers, construction firms are working on their sustainability strategy, getting to grips with scopes of emissions, working towards net zero carbon and battling to decarbonise their operations. Whilst the work is incredibly important, some are struggling with the terminology, and distinguishing between terms when discussing strategy.

Scott Wilson, Europe Head of Sustainability, Black & White Engineering, has shared his thoughts with Construction Digital as he tries to demystify the ever-evolving world of sustainability in construction.

Wilson has an MEng in mechanical engineering, he is an accredited BREEAM assessor, a Low Carbon Consultant (LCC), and a Level 5 Non-Domestic Low Carbon Energy Assessor (LCEA).

With a background in building services, he helps to deliver low-carbon and sustainable buildings while considering the feasibility and affordability of a range of solutions. His extensive energy modelling experience, including operational energy prediction, thermal comfort, building regulation compliance, and daylight analysis, brings him a good understanding of what works, enabling him to take a holistic approach to find the optimum outcome on each project.

“Carbon neutral is probably the easiest to achieve, particularly if you have deep pockets. Carbon neutrality simply means that all calculated carbon emissions have been offset to effectively neutralise the impact of them. The problem with this is it does not necessarily require any actual carbon reduction and carbon offsets can be purchased for as little as 10 USD per tonne,” he says.

“The term net zero expands the definition to include all greenhouse gases usually expressed as a CO2 equivalent value. Furthermore, net zero is typically understood to require a reduction in carbon emissions first, with offsets only being the final step in the greenhouse gas mitigation hierarchy.

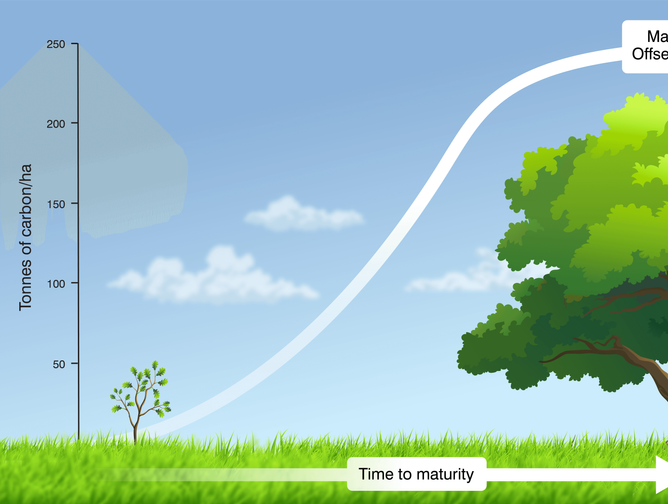

“The differences are important as there are clear differences in outcomes. A company or building can claim to be carbon neutral by simply purchasing offsets. This often does nothing in the immediate term to reduce the emissions being emitted and contributing to climate change. For example, one of the preferred schemes is to plant trees. On face value this is a perfect initiative; trees absorb CO2 as they grow, they create habitats for wildlife and can reduce the ‘heat island’ effect which occurs when cities replace natural land cover with dense concentrations of buildings that absorb and retain heat.

“The problem with this is that the typically quoted value of around one tonne of CO2 per tree is not realised until the tree is fully grown. This can take over 100 years, by which point, the damage has already been done.”

Despite the issues around carbon offsetting, Wilson does believe that it has a place in the solution.

“It can be an excellent funding mechanism for decarbonisation projects that may otherwise never see the light of day. Carbon offsets should still be utilised but only as a last resort, after all other avenues for active carbon reduction have been considered.”

Putting fabric first, second

The construction industry is facing an urgent need to prioritise immediate carbon emissions over annual emissions from building operations, due in part to the delayed benefits from carbon offsetting products, and the immediate negative impact that construction can have — and on a large scale.

“The traditional “fabric first” approach has been an industry standard in reducing a building's energy demand by focusing on the building's envelope to minimise heat loss. This approach has led to strategies like increasing insulation to levels seen in passive house standards. However, with the ongoing shift towards a decarbonising grid, this emphasis on insulation may need to be reevaluated,” says Wilson.

“Carbon emissions from building operations are continually decreasing as energy production becomes cleaner. Consequently, the added insulation's impact is diminishing, sometimes leading to diminishing returns. A prime example is the move from double to triple glazing, which requires up to 50% more glass and thicker insulation, resulting in an inherent increase in embodied carbon.

“These increases in embodied carbon can take decades to pay back through operational energy savings and may never be achieved in some buildings' lifespan. This brings forth a need for a more nuanced approach that doesn't solely focus on U-values but also accounts for the whole life cycle impacts of the building. For instance, the construction industry can explore alternative materials like aerogels made from construction waste or wood fibres, which provide insulation with lower embodied carbon. Such innovative solutions can maintain high levels of insulation while reducing the overall carbon footprint."

“The traditional hierarchy of design, which consists of reducing demand, improving efficiency, and incorporating renewable energy, also needs to be re-evaluated. The problem lies in its lack of consideration for the building's whole life carbon perspective. Different buildings have different needs. For example, an old building with a gas-based system may still benefit significantly from insulation improvements, while a new, airtight building heated by high-efficiency heat pumps may not and such improvements are likely to increase the embodied carbon with minimal impact on the operational energy.

“This variance emphasises the importance of life cycle carbon assessments early in the design process. Such assessments should inform major design decisions through construction, considering not only the building's operational phase but also its construction, maintenance, and end-of-life stages. By shifting the focus from solely operational carbon to a more comprehensive life cycle view, the industry can better align with global sustainability goals.

“The case for whole life carbon assessments is clear and assessing a building from cradle to grave is the only way to truly assess its impact, while designing with cradle-to-cradle principles in mind allows the design to consider the future and ensures that at the end of a building’s lifecycle, building materials can repurposed for future use as part of a circular economy.

“To do this, the industry will need to rethink not only the design of the buildings, but the approach to design by incorporating the necessary expertise much earlier in the design process. It requires a major shift where short-term energy efficiency measures are balanced with long-term considerations of embodied carbon. The move towards considering immediate carbon emissions as more critical is not just a technological challenge but also a cultural one, requiring collaboration, innovation, and a willingness to redefine traditional practices. Only by embracing this holistic approach can the construction industry genuinely contribute to a low carbon future and reduce the greenwashing implications that can arise from only focusing on the more visible aspects of a building.”

******

Make sure you check out the latest industry news and insights at Construction Digital and also sign up to our global conference series - Manufacturing LIVE 2024

******

Construction Digital is a BizClik brand

*****

- What Is It Like To Be A Woman In Construction?Construction Projects

- McKinsey Reports Global Material Circularity Has Shrunk 10%Sustainability & Green Building

- Bechtel & Westinghouse Boost Nuclear Construction in EuropeConstruction Projects

- Google announces US$1bn Sustainable Data Centre ProjectConstruction Projects